The Strategic Value of Metal Services for Optimizing Operations

Every business struggles to balance its core priorities with time-consuming production tasks. When production ramps up, partnering with a steel & metal service center can make a huge difference by saving time and optimizing resources.

The best metal service centers don’t just provide raw material s— they offer specialized support like CNC machining, milling, and sawing, helping businesses avoid big equipment costs and outdated tools. Working with the right center gives you more than materials; it gives you access to steel services and expert advice.

That said, not all metal service centers are created equal. Choosing the right partner can turn a basic vendor into a real strategic advantage. In this article, we’ll break down the benefits of adding metal services to your supply chain and how it can boost your operations.

6 Strategic Advantages of Value-Added Metal Services

Optimizing your supply chain requires a steel & metal service center that goes beyond basic delivery. The right partner increases quality and efficiency through advanced CNC machinery, milling, and sawing.

Here are six advantages on how a metal goods service center strengthens your operations:

1. Precision and Accuracy

To ensure metal services are delivered with exact specifications, leading metal service centers utilize efficiency systems like KanBan. This methodology organizes components systematically, ensuring that your steel & metal service center processes orders with maximum accuracy and minimal waste.

2. Logistical Efficiency and Time Savings

For businesses in Northeastern PA and Southern Tier NY, partnering with a local metal service center reduces transit times and mitigates offshore supply chain risks. Utilizing local Steel Services ensures faster turnaround and supply chain resilience.

By outsourcing to a metal goods service center, your internal teams can focus on core projects. The proximity of your steel & metal service center allows for rapid deployment of CNC machinery, milling, and sawing tasks, ensuring deadlines are met without internal bottlenecks.

3. Cost Reduction and ROI

Operational efficiency drives profitability. Partnering with a metal service center for industrial metal services guarantees that fabrication is completed correctly the first time. Access to expert CNC machinery, milling, and sawing eliminates the need for internal rework.

Delegating these tasks to a metal goods service center allows your staff to specialize in their primary roles. This division of labor, facilitated by professional Steel Services, reduces overhead and maximizes workforce productivity.

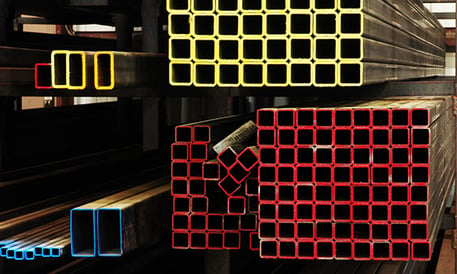

4. Extensive On-Site Inventory

A good metal service center maintains strategic inventory levels tailored to client needs. Unlike standard vendors, metal service centers with large inventories can reduce lead times significantly. A reliable steel & metal service center ensures you have materials when demand peaks, protecting your production schedule.

5. Scalability and Availability

While walk-in requests are possible, strategic planning with your metal services provider ensures capacity alignment. Engaging a metal goods service center early in the project lifecycle allows for accurate forecasting. A capable steel & metal service center can scale production to meet complex requirements and tight timelines.

6. Comprehensive Value-Added Services

Unforeseen project scope changes require agility. When you outsource to a partner with on-site CNC machinery, milling, and sawing, these adjustments are handled seamlessly.

This can mean resolving a metal issue you didn’t even know about, all with minimal time lost.

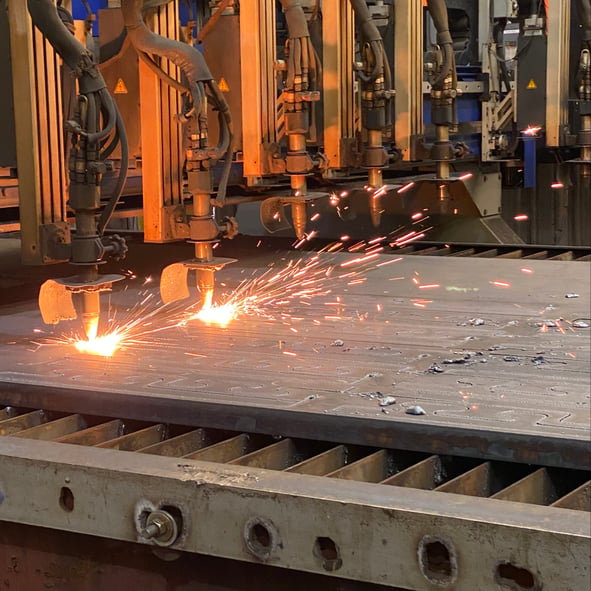

A metal service company offers many additional on-site services, including:

- Shearing and Kitting

- Plate-burning

- Sand-blasting

- CNC machinery, milling, and sawing operations

Metal Services FAQ: Strategic Decision MakingHow do I assess a provider's capabilities? What is the ROI of outsourcing to metal service centers? What should I ask a potential partner? |

Optimizing Operations with the Right Partner

The choice of a metal service center directly influences operational reliability. From dependable Steel Services to advanced CNC machinery, milling, and sawing, the right partner is essential.

Metal service centers act as an extension of your facility. Access to experienced staff and comprehensive metal services ensures project success.

Build a Trusted Partnership with State Line

As a family-owned business with a long-standing history, State Line Supply Co. has served various industries with reliable, full-service metal goods service center support. Whether you're exploring outsourcing or need specific capabilities, our team is here to guide you.

Contact us today to learn how our services can support your next project with confidence.

(Editor’s Note: This blog was originally published in September 2023 and was updated in December 2025.)